Dry vs. Wet Milling – What’s the Difference?

Milling is a key technique used to break down raw materials into finer particles for various industrial applications. But when it comes to milling, one size doesn’t fit all. The two main methods – dry and wet milling – each bring unique benefits and challenges depending on the material, desired outcome, and specific industry requirements.

What is Dry Milling?

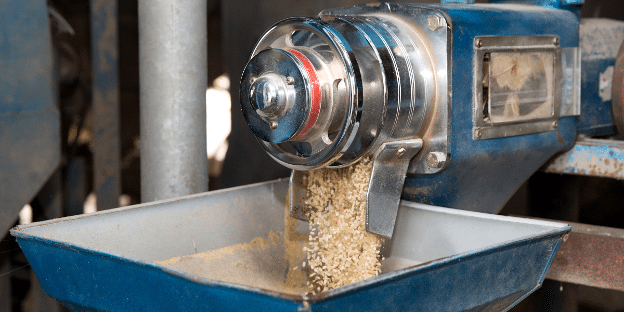

Dry milling is a process that uses friction, impact, or compressive force to break down materials without adding any liquids. During this method, materials are processed in a completely dry environment, which can be an advantage in applications where moisture could harm the product or impact its quality. Dry milling is commonly used in the production of materials like powders, minerals, and certain types of pharmaceuticals.

Benefits of Dry Milling:

- Less Contamination: Since no water or solvents are used, the risk of introducing contaminants is minimized, making it ideal for sensitive materials.

- Lower Cost: Dry milling generally has lower operational costs as it requires less equipment and doesn’t involve water or drying steps.

- No Drying Required: Because no liquid is used, the end product is ready to use immediately after milling without additional drying time.

Limitations of Dry Milling:

- Heat Generation: The friction and impact in dry milling can generate heat, which may affect heat-sensitive materials.

- Lower Efficiency with Fine Particles: Dry milling may not be as effective at achieving extremely fine particle sizes as wet milling.

What is Wet Milling?

Wet milling, on the other hand, involves using water or another liquid to aid in the grinding process. This liquid is added to the milling chamber to help cool the material and grinding equipment, minimize dust, and achieve a finer particle size. Wet milling is particularly useful for materials that are heat-sensitive, abrasive, or that tend to form dust when processed.

Benefits of Wet Milling:

- Effective Cooling: The added liquid helps dissipate heat, making wet milling ideal for materials that are sensitive to temperature changes.

- Enhanced Particle Size Reduction: Wet milling achieves finer, more uniform particles compared to dry milling.

- Reduced Dust: By containing dust in the liquid, wet milling provides a cleaner environment, which is essential in industries like pharmaceuticals or food production.

Limitations of Wet Milling:

- Increased Cost: Wet milling requires additional equipment to handle liquids and often includes an extra drying step post-processing.

- Potential Contamination: Introducing a liquid means there’s a higher risk of contamination, which may require strict handling procedures.

- Additional Drying Step: Once milling is complete, the product typically needs to be dried, which can add time and complexity to the process.

Comparing Dry and Wet Milling for Different Industries

Choosing between dry and wet milling depends largely on the industry, material, and specific end goals. Here are a few key industries and how they might choose between the two:

1. Pharmaceuticals

Preference: Often wet milling.

Why: Wet milling offers finer particle sizes, which can enhance the bioavailability of pharmaceutical compounds. It also minimizes dust, making it safer for handling and production.

2. Mining and Minerals

Preference: Primarily dry milling.

Why: In the mining industry, dry milling is commonly used as it reduces operational costs and is ideal for large-scale operations that can tolerate some heat generation.

3. Food Processing

Preference: Both methods.

Why: The choice depends on the product; dry milling is suitable for grains, while wet milling is often used for pastes, starch, and sugar processing to achieve a uniform texture and prevent overheating.

4. Chemicals and Powders

Preference: Generally dry milling.

Why: Dry milling reduces contamination and is effective for powders, pigments, and fillers. However, wet milling may be chosen for certain chemicals where a finer, more controlled particle size is needed.

Choosing the Right Method for Your Application

When it comes to picking between dry and wet milling, a few main things to keep in mind are:

- Material Sensitivity: If the material is heat-sensitive or abrasive, wet milling could be the better choice since it helps control temperature and wear.

- Desired Particle Size: Need ultra-fine particles? Wet milling might give you that edge.

- Cost and Time: Dry milling tends to be more budget-friendly and quicker – no extra drying steps or liquid handling required.

- Contamination Risk: Dry milling can help minimize contamination risks because it avoids introducing any liquids.

M&M Milling’s Expertise in Dry and Wet Milling

M&M Milling has the expertise and high-quality milling equipment to meet your production goals. With services that range from particle size reduction to custom blending and powder processing, we work closely with clients to provide the best milling solution for their application.

Have questions about which milling method is best for your project? M&M Milling offers both dry and wet milling solutions tailored to your needs. Contact us today to learn more about our toll manufacturing company and how we can help you achieve high-quality, consistent results in your processing operations.